In this example, I will be using as my my test material a 3mm black acrylic which has a kerf of 0.2mm.

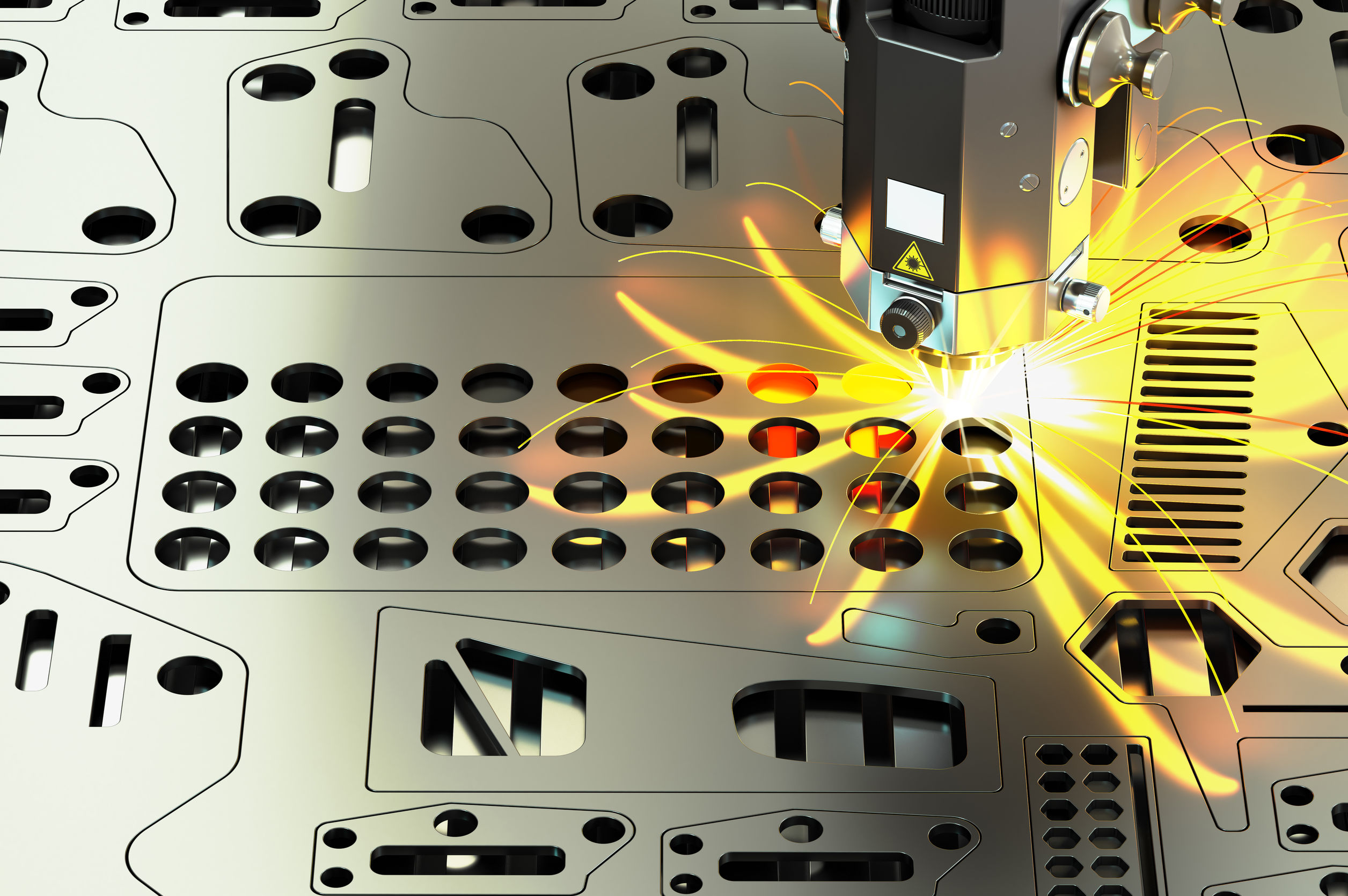

Of course, different materials and different cutters will have different kerf, you should test. Helpfully, Ponoko has experimented with their various materials and has created a table of how much material is burned away by the cutting laser (kerf) if you are using their services. I warned about the issue of material removed by the cutting process, I decided to test with a sheet in one colour first. A third colour for the frame might be nice. My design calls for pieces cut from 2 different colours to be put together and fit precisely. Not 3D assemblage, but a 2D graphic type design (see below). I wanted to make a laser cut Plexiglas design with interlocking and inset pieces using the Ponoko cutting service.

0 kommentar(er)

0 kommentar(er)